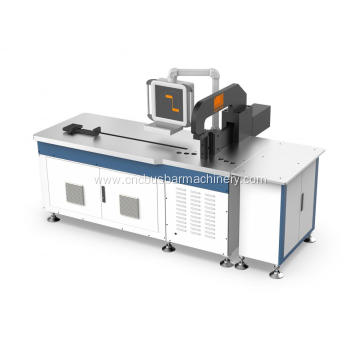

Model No.: EMAC-BB

Brand: Euro-Asia

Machinable material: Alloy

Old and new: New

place of origin: China

degree of automation: Automatic

Additional features: Machining

Certification: Ce, CE

warranty period: 1 Year

Out-of-warranty service: Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service

Core selling point: High-Accuracy

Applicable industry: Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction Works, Energy & Mining, Other, Advertising Company

Where to provide local services (in which countries are there overseas service outlets): India, Russia

Showroom location (in which countries are there sample rooms overseas): None

Marketing type: Hot Product 2019

Mechanical test report: Provided

Video factory inspection: Provided

Core component warranty period: 1 Year

Core components: Bearing, Motor, Pump, Gear, Plc, Pressure Vessel, Engine, Other, Gearbox

Suitable for: Aluminum

Condition: New

Automation: Automatic

Type: Hydraulic Bending Machine

Total Power: 7.2KW

Total Weight: 2700KGS

Nominal Force: 400KN

Max Bending Stroke: 250mm

Stroke Of Side Striker: 2000mm